- Home Page

- Company Profile

-

Our Products

- Oxidized Polyethylene Wax

- Pvc impact modifier

- MBS Impact Modifier

- pvc impact modifier

- PVC Impact Modifier

- Chlorinated Polyethylene

- Acrylic Impact Modifier

- ACM Impact Modifier

- CPE 135A

- ACM Impact Modifier

- Acrylic Impact Modifier

- MBS RESIN

- Acrylic Impact Modifier

- Chlorinated polyethylene

- ACM Impact Modifier

- PVC Impact Modifier

- MBS Impact Modifier

- PVC Foaming Regulator

- Acrylic Processing Aid

- Acrylic Processing Aid

- High molecular weight processing aid

- PVC Foaming Regulator

- PVC Processing Aid

- Processing Aid ACR401

- Lubricant Processing Aid

- San Processing Aid

- Pvc Processing Aid

- Impact Modifier for PVC Pipe

- High Molecular Weight Processing Aid

- PVC Lubricating Processing Aids

- Acrylic Processing Aids

- SAN Processing Aid

- Acrylic Processing Aid

- Processing Aid

- Lubricant Processing Aid

- Acrylic Processing Aid

- Hydrotalcite

- ASA Resin

- Calcium stearate

- PVC Raw Material

- Chlorinated Polyethylene

- NC Blowing Agent

- Additives for PVC

- Antioxidant SBM

- MBS Resin

- MBS Impact Modifier

- CPE 135B

- PVC Additives

- Calcium Stearate

- PVC Compound Stabilizer

- Methyl tin stabilizer

- PVC Raw Material

- Additives for PVC

- ASA Granule

- PVC Foaming Regulator

- PVC Stabilizer

- Dike tone

- Chlorinated Polyethylene

- AC Blowing Agent

- Hydrotalcite HTC-3

- Low Density Oxidized Polyethylene

- High Density Oxidized Polyethylene

- PVC Foaming Agent

- PVC Heat Stabilizer

- Synthetic Hydrotalcite

- Chlorinated Polyethylene

- CPVC 1

- ASA Resin

- Ca Zn Stabilizer

- PVC Additives

- Wax

- Chlorinated Polyethylene CPE135A

- PVC Stabilizer

- Oxidized Polyethylene Wax

- More Info

- Contact Us

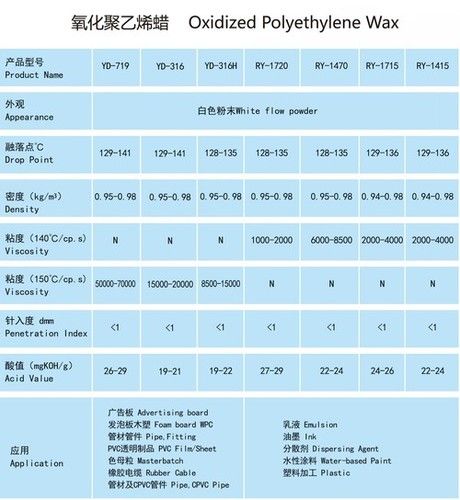

Oxidized Polyethylene wax

1250.00 - 1550.00 USD ($)/Ton

Product Details:

- Physical Form Powder

- Shelf Life 2 Years

- Grade Industrial Grade

- Smell Stimulus

- Melting Point 100-105 Degree Celcius

- Application Industrial Plastic

- CAS No 9002-88-4

- Click to view more

X

Oxidized Polyethylene wax Price And Quantity

- 10 Ton

- 1250.00 - 1550.00 USD ($)/Ton

Oxidized Polyethylene wax Product Specifications

- Industrial Grade

- Stimulus

- White

- 99.5%

- 200-815-3

- Cool Dry Place

- Clear Powder

- Industrial Plastic

- Powder

- 2 Years

- 9002-88-4

- Chemical Additive Agent

- 100-105 Degree Celcius

- Lubricant Additive

Oxidized Polyethylene wax Trade Information

- Shandong, China

- Letter of Credit (L/C) Telegraphic Transfer (T/T) Western Union Cash Advance (CA)

- 1000000 Ton Per Month

- 15-45 Days

- Yes

- Within a certain price range free samples are available

- As per customers requirement

- Australia North America Eastern Europe Western Europe Middle East Central America South America Asia

- All India

Product Description

Oxidized polyethylene wax is a new kind of excellent polar wax. Due to a certain amount of carbonyl and hydroxyl groups in the molecular chain of oxidized polyethylene wax, the solubility of oxidized polyethylene wax with fillers, pigments and polar resins has been significantly improved. The wettability and dispersibility of polar system are better than that of polyethylene wax, and they also have coupling property, which is equivalent to Honeywell a-c wax.

Ope wax has special properties such as low viscosity, high softening point, good hardness, non-toxic, good thermal stability, low volatility at high temperature, excellent dispersibility for fillers and pigments, excellent external lubrication, strong internal lubrication and coupling, which can improve the production efficiency of plastic processing and reduce the production cost.

There are some functional groups in the molecular chain of oxidized pe wax, so the solubility of oxidized polyethylene wax and polar resin is improved significantly, which is better than polyethylene wax. In the plastic processing industry, the internal and external lubrication of PVC is relatively balanced; the lubricity of adding oxidized polyethylene wax to rigid transparent and opaque PVC formula is better than other lubricants. It is widely used in the production of PE, PVC cable, PVC profile and pipe, which is a new excellent plastic processing lubricant.

For TDS and MSDS, you can contact our Sales and Marketing Department or you can reach us through the contact page .

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese