- Home Page

- Company Profile

-

Our Products

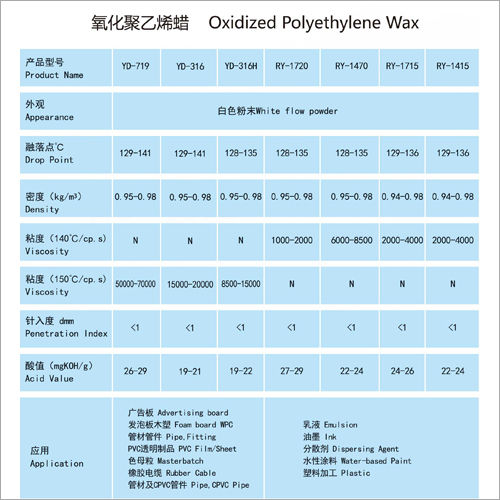

- Oxidized Polyethylene Wax

- Pvc impact modifier

- MBS Impact Modifier

- pvc impact modifier

- PVC Impact Modifier

- Chlorinated Polyethylene

- Acrylic Impact Modifier

- ACM Impact Modifier

- CPE 135A

- ACM Impact Modifier

- Acrylic Impact Modifier

- MBS RESIN

- Acrylic Impact Modifier

- Chlorinated polyethylene

- ACM Impact Modifier

- PVC Impact Modifier

- MBS Impact Modifier

- PVC Foaming Regulator

- Acrylic Processing Aid

- Acrylic Processing Aid

- High molecular weight processing aid

- PVC Foaming Regulator

- PVC Processing Aid

- Processing Aid ACR401

- Lubricant Processing Aid

- San Processing Aid

- Pvc Processing Aid

- Impact Modifier for PVC Pipe

- High Molecular Weight Processing Aid

- PVC Lubricating Processing Aids

- Acrylic Processing Aids

- SAN Processing Aid

- Acrylic Processing Aid

- Processing Aid

- Lubricant Processing Aid

- Acrylic Processing Aid

- Hydrotalcite

- ASA Resin

- Calcium stearate

- PVC Raw Material

- Chlorinated Polyethylene

- NC Blowing Agent

- Additives for PVC

- Antioxidant SBM

- MBS Resin

- MBS Impact Modifier

- CPE 135B

- PVC Additives

- Calcium Stearate

- PVC Compound Stabilizer

- Methyl tin stabilizer

- PVC Raw Material

- Additives for PVC

- ASA Granule

- PVC Foaming Regulator

- PVC Stabilizer

- Dike tone

- Chlorinated Polyethylene

- AC Blowing Agent

- Hydrotalcite HTC-3

- Low Density Oxidized Polyethylene

- High Density Oxidized Polyethylene

- PVC Foaming Agent

- PVC Heat Stabilizer

- Synthetic Hydrotalcite

- Chlorinated Polyethylene

- CPVC 1

- ASA Resin

- Ca Zn Stabilizer

- PVC Additives

- Wax

- Chlorinated Polyethylene CPE135A

- PVC Stabilizer

- Oxidized Polyethylene Wax

- More Info

- Contact Us

High Density Oxidized Polyethylene

4.00 - 12.50 USD ($)/Kilograms

Product Details:

- Chemical Name Chemical Auxiliary Agent

- Other Names Oxidized polyethylene wax

- CAS No 68441-17-8

- Classification Chemical Auxiliary Agent

- Color White

- Form Wax

- Application polish, textile, leather and paper

- Click to view more

X

High Density Oxidized Polyethylene Price And Quantity

- 4.00 - 12.50 USD ($)/Kilograms

- 1000 Kilograms

High Density Oxidized Polyethylene Product Specifications

- White

- polish, textile, leather and paper

- Wax

- Oxidized polyethylene wax

- Chemical Auxiliary Agent

- Chemical Auxiliary Agent

- 68441-17-8

High Density Oxidized Polyethylene Trade Information

- Shandong, China

- Letter of Credit at Sight (Sight L/C) Western Union Telegraphic Transfer (T/T)

- 200000 Kilograms Per Month

- 7-12 Days

- Yes

- Within a certain price range free samples are available

- Polyethene bag 20 kg Pallet 1000 kg (50 bags) Big Bag 500 kg

- Asia Australia North America Eastern Europe Middle East Central America South America Western Europe Africa

- All India

Product Description

High density oxidized polyethylene is a new type of polymer oxidized polymer, which is a functional processing aid with excellent performance. It is suitable for PVC products to increase plasticizing time and improve the later demoulding. It can reduce the adhesive force of thermoplastic melting, increase the output, and improve the gloss and appearance of the finished product. It can greatly increase plasticizing time and reduce torque. It can improve the later demoulding performance. High density oxidized polyethylene wax is suitable for PVC foam board, PVC advertising board, PVC transparent sheet, PVC transparent film, PVC high calcium products, PVC floor and other products. Replace the imported oa6 and oa3 by the same amount.

High density oxidized polyethylene YD719 is a kind of oxidation polymer with excellent performance as a functional processing aid.

Physicochemical Properties

Index/Product Name | YD719 |

Appearance | White powder |

Acid Number mg KOH/g | 26-29 |

Hardness@25-77 | 0.5dmm |

Drop Point ,Mettler | 129-141 |

Density | 0.95-0.98g/cc |

Vicosity@150 cp.s | 50000-70000 |

Product Benefits and Application

YD719 can reduce the adhesion of the thermoplastic melt, improve the output; YD719 can improve the luster, improve the appearance of the finished product. YD719 can greatly increase the fusion, while greatly reducing torque.

YD719 can improve the late release performance, etc.

Equivalent

Honeywell A-C 307

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese