- Home Page

- Company Profile

-

Our Products

- Oxidized Polyethylene Wax

- Pvc impact modifier

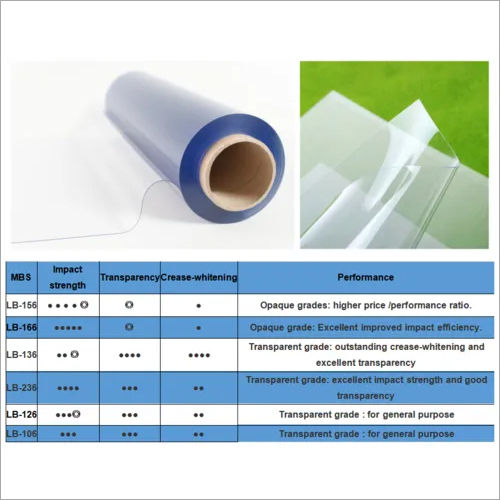

- MBS Impact Modifier

- pvc impact modifier

- PVC Impact Modifier

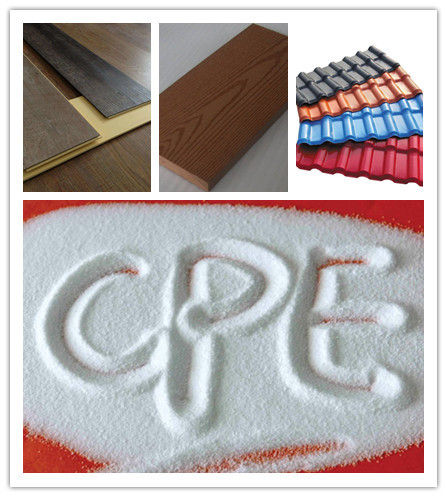

- Chlorinated Polyethylene

- Acrylic Impact Modifier

- ACM Impact Modifier

- CPE 135A

- ACM Impact Modifier

- Acrylic Impact Modifier

- MBS RESIN

- Acrylic Impact Modifier

- Chlorinated polyethylene

- ACM Impact Modifier

- PVC Impact Modifier

- MBS Impact Modifier

- PVC Foaming Regulator

- Acrylic Processing Aid

- Acrylic Processing Aid

- High molecular weight processing aid

- PVC Foaming Regulator

- PVC Processing Aid

- Processing Aid ACR401

- Lubricant Processing Aid

- San Processing Aid

- Pvc Processing Aid

- Impact Modifier for PVC Pipe

- High Molecular Weight Processing Aid

- PVC Lubricating Processing Aids

- Acrylic Processing Aids

- SAN Processing Aid

- Acrylic Processing Aid

- Processing Aid

- Lubricant Processing Aid

- Acrylic Processing Aid

- Hydrotalcite

- ASA Resin

- Calcium stearate

- PVC Raw Material

- Chlorinated Polyethylene

- NC Blowing Agent

- Additives for PVC

- Antioxidant SBM

- MBS Resin

- MBS Impact Modifier

- CPE 135B

- PVC Additives

- Calcium Stearate

- PVC Compound Stabilizer

- Methyl tin stabilizer

- PVC Raw Material

- Additives for PVC

- ASA Granule

- PVC Foaming Regulator

- PVC Stabilizer

- Dike tone

- Chlorinated Polyethylene

- AC Blowing Agent

- Hydrotalcite HTC-3

- Low Density Oxidized Polyethylene

- High Density Oxidized Polyethylene

- PVC Foaming Agent

- PVC Heat Stabilizer

- Synthetic Hydrotalcite

- Chlorinated Polyethylene

- CPVC 1

- ASA Resin

- Ca Zn Stabilizer

- PVC Additives

- Wax

- Chlorinated Polyethylene CPE135A

- PVC Stabilizer

- Oxidized Polyethylene Wax

- More Info

- Contact Us

Chlorinated polyethylene

1150.00 - 1350.00 USD ($)/Ton

Product Details:

- Shape Granules

- Smell Stimulus

- Grade Industrial Grade

- Application Industrial Plastic Textile Industry

- Physical Form Powder

- Shelf Life 2 Years

- CAS No 102-77-2

- Click to view more

X

Chlorinated polyethylene Price And Quantity

- 1150.00 - 1350.00 USD ($)/Ton

- 5 Ton

Chlorinated polyethylene Product Specifications

- White

- Clear Powder

- Industrial Plastic Textile Industry

- Plastic Auxiliary Agents

- Granules

- Stimulus

- Industrial Grade

- Impact modifier

- 102-77-2

- 2 Years

- 99.9%

- Room Temperature

- Powder

Chlorinated polyethylene Trade Information

- Shandong, China

- Letter of Credit (L/C) Western Union Telegraphic Transfer (T/T) Cash Advance (CA)

- 10000 Ton Per Month

- 7-12 Days

- Yes

- Within a certain price range free samples are available

- 25 Kg/kraft bag

- Western Europe Australia North America Eastern Europe Central America Middle East South America Asia Africa

- All India

Product Description

Chlorinated polyethylene (CPE) is a kind of powder product which uses HDPE to suspend and chlorinate in water phase. With the increase of chlorination degree, the original crystalline HDPE gradually becomes an amorphous elastomer. The content of CL in CPE used as toughening agent is generally 25-45%. CPE has a wide source and low price. Besides toughening effect, it also has cold resistance, weather resistance, fire resistance and chemical resistance. At present, CPE is the leading impact modifier in China, especially in PVC pipe and profile production, most factories use CPE. The addition amount is generally 5-15. CPE can be used in combination with other toughening agents, such as rubber, EVA, etc., with better effect, but rubber additives are not resistant to aging.

CPE is chlorinated polyethylene, which is made of HDPE by partial chlorination. Due to the existence of chlorine atom, CPE has softness and some rubber properties, and makes CPB a polar polymer with the same polar group as PVC, increasing the compatibility with PVC, so the polymer chain can maintain enough van der Waals force, thus improving the impact resistance and toughening effect of PVC. Moreover, CPE has the function of accelerating PVC melting and plasticizing. With the increase of CPE content, the plasticizing time is shortened, the plasticizing torque and equilibrium torque are increased, and the viscosity of plasticized melt is increased.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese